Taiwan Semiconductor Manufacturing Company (TSMC) has announced a significant expansion of its investment in Arizona, committing over $65 billion to develop three advanced semiconductor fabrication plants. The project is supported by substantial funding from the U.S. government through the CHIPS and Science Act, aiming to strengthen domestic chip manufacturing capabilities.

The expanded plan includes the construction of a third fabrication plant, or "fab," in Phoenix. This move increases the company's initial investment commitment of $40 billion, signaling a major step toward establishing a leading-edge semiconductor ecosystem in the United States.

Key Takeaways

- Total Investment: TSMC's investment in Arizona now exceeds $65 billion, a substantial increase from the original $40 billion plan.

- Third Factory: The company will build a third semiconductor fab in Phoenix, adding to the two previously announced facilities.

- Advanced Technology: The new fabs will produce the world's most advanced chips, including 2-nanometer process technology, crucial for AI and high-performance computing.

- U.S. Government Funding: The project is backed by up to $6.6 billion in direct grants and $5 billion in loans under the CHIPS and Science Act.

- Job Creation: The investment is expected to create approximately 6,000 direct high-tech manufacturing jobs and tens of thousands of construction and indirect jobs.

Details of the Expanded Project

TSMC's revised commitment marks one of the largest foreign direct investments in a completely new project in U.S. history. The decision to add a third fab underscores the company's confidence in the long-term viability of semiconductor manufacturing in Arizona.

The first fab is on track to begin production using 4-nanometer technology in the first half of 2025. The second fab, previously announced to produce 3nm chips, will now also manufacture more advanced 2nm technology, with production slated to begin in 2028.

The newly announced third fab will further advance this roadmap, producing chips using 2nm or even more advanced processes. Production at the third facility is expected to start by the end of the decade. This tiered approach ensures a continuous pipeline of cutting-edge chip production on U.S. soil.

Project Timeline

- Fab 1: Production of 4nm chips begins in H1 2025.

- Fab 2: Production of 3nm and 2nm chips begins in 2028.

- Fab 3: Production of 2nm or more advanced chips begins before 2030.

Strategic U.S. Government Support

The expansion is directly supported by a preliminary agreement with the U.S. Department of Commerce under the CHIPS and Science Act. This legislation was designed to incentivize the domestic production of semiconductors to reduce reliance on foreign supply chains, particularly in East Asia.

Under the agreement, TSMC Arizona will receive up to $6.6 billion in direct federal funding. The company is also eligible for up to $5 billion in federal loans, providing significant financial stability for the massive undertaking. Furthermore, TSMC plans to claim an Investment Tax Credit of up to 25% on qualified capital expenditures.

"For the first time ever, we will be making the most advanced semiconductor chips on the planet here in the United States of America," stated U.S. Secretary of Commerce Gina Raimondo. She emphasized that these chips are essential for powering artificial intelligence and the broader technology economy.

What is the CHIPS Act?

The CHIPS and Science Act of 2022 is a U.S. federal law that allocates roughly $280 billion in new funding to boost domestic research and manufacturing of semiconductors. Its primary goal is to enhance U.S. economic and national security by reducing dependence on foreign chip producers.

This federal backing is crucial for offsetting the higher costs associated with building and operating advanced fabs in the U.S. compared to Asia. According to TSMC Chairman Dr. Mark Liu, the CHIPS Act provides the company with the opportunity to make this unprecedented investment and offer its most advanced manufacturing technologies in the United States.

Economic and Technological Impact

The economic ripple effects of TSMC's investment are expected to be substantial. The project is projected to create around 6,000 direct, permanent high-tech jobs. These roles will include engineers, technicians, and operations staff who will manage the complex fabrication processes.

Beyond the direct hires, the construction phase alone is expected to generate over 20,000 jobs. The development of a local supplier ecosystem to support the three fabs will create tens of thousands of additional indirect jobs in Arizona and across the country.

Fueling the Next Generation of Technology

The significance of producing 2-nanometer chips in the U.S. cannot be overstated. These semiconductors are foundational for future technological advancements. A smaller nanometer process allows for more transistors to be packed onto a single chip, resulting in greater processing power and energy efficiency.

Applications for Advanced Chips

- Artificial Intelligence (AI): Training and running complex AI models.

- High-Performance Computing (HPC): Powering supercomputers for scientific research.

- Mobile Devices: Enabling next-generation smartphones and tablets.

- Automotive: Supporting advanced driver-assistance systems (ADAS) and autonomous driving.

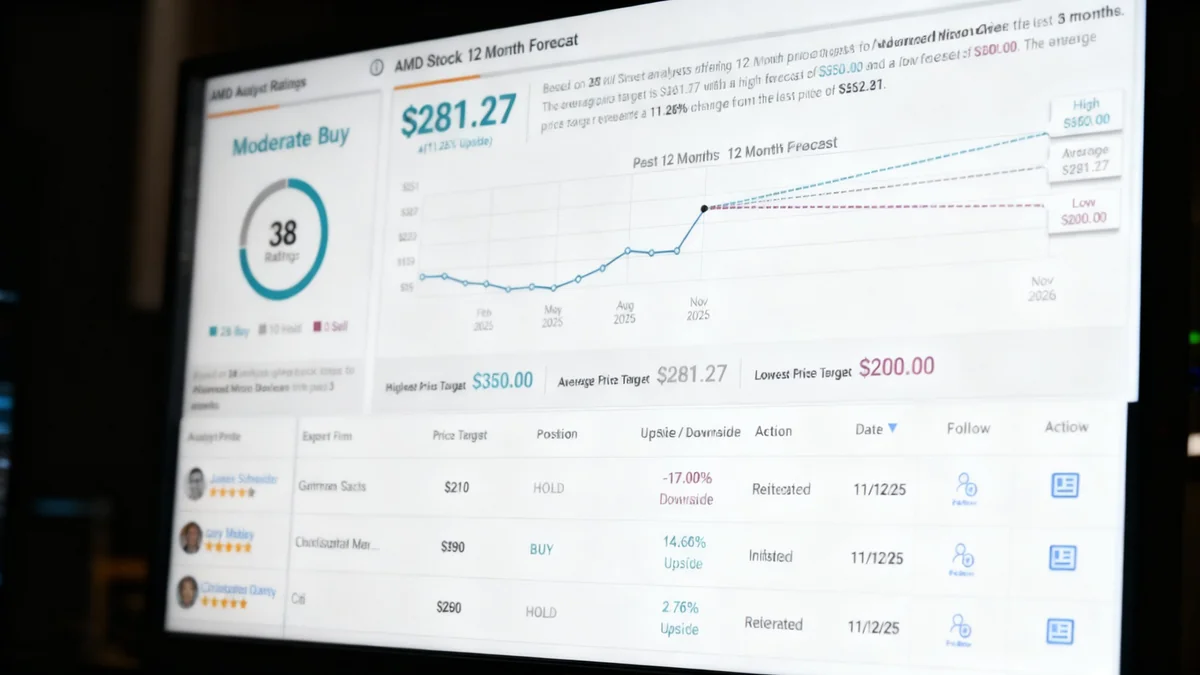

Major U.S. technology companies, including Apple, NVIDIA, AMD, and Qualcomm, are key TSMC customers. Having a reliable, domestic source for the most advanced chips will strengthen their supply chains and support their innovation roadmaps.

Overcoming Challenges and Looking Ahead

The path to establishing this mega-site has not been without difficulties. TSMC previously announced delays for its first Arizona fab, citing shortages of skilled labor and ongoing negotiations with local unions. The initial production timeline was pushed from 2024 to 2025.

However, the new agreement and expanded investment suggest that the company and its government partners have found a way forward. The project includes a commitment by TSMC to invest in training the local workforce, ensuring a pipeline of skilled talent to operate the sophisticated facilities.

This investment is part of a broader global trend of nations working to secure their own semiconductor supply chains. The U.S. government is also funding projects by other major chipmakers like Intel and Samsung, creating a competitive and robust domestic manufacturing landscape.

By bringing the most advanced chipmaking technology to American shores, the TSMC Arizona project represents a critical step in re-establishing U.S. leadership in an industry it once pioneered. The success of these fabs will be a key indicator of the nation's ability to compete in the 21st-century global economy.